This past February, when Ontario Made announced the winners of its inaugural awards, Sudbury’s Brown’s Concrete was the sole Northern Ontario business among them.

Launched in 2020 after COVID hit, Ontario Made is an initiative of the Canadian Manufacturers & Exporters (CME).

With Ontario producers rapidly losing business during the pandemic, the Ontario Made database was created as a way to encourage consumers to support local manufacturers, and the awards stepped up the recognition for those companies that really pulled out all the stops.

For Ken Scott, the long-time office manager at Brown’s, the award was a humbling acknowledgement of the company’s work over a century-plus of operation.

“That Ontario Made award, as much as it says ‘Brown’s Concrete’ on it, everyone in Northern Ontario owns a piece of that award,” Scott said.

“It would never have happened that we could have been competitive in the provincial marketplace if it hadn’t been for Northern Ontario and the support that they’ve shown us.”

As its name suggests, Brown’s produces a range of concrete items, including blocks, paving stones, and retaining wall units, and also distributes related Ontario-made products like brick, designer stone, and other landscaping and construction materials. Their products are sold and used across Ontario and into the upper United States.

As news of their win has spread, so has Brown’s network and reputation, Scott said.

Over the last few months, he’s been busily fielding inquiries from prospective clients, particularly those south of Parry Sound, who are newly curious about their products and interested in establishing partnerships.

“I think our base is really strong in Sudbury; I think what (the award has) done is maybe open the eyes of some companies in the rest of the province,” Scott said. “We’ve been really fortunate.”

At 115 years old, Brown’s is hardly a newcomer to the industry.

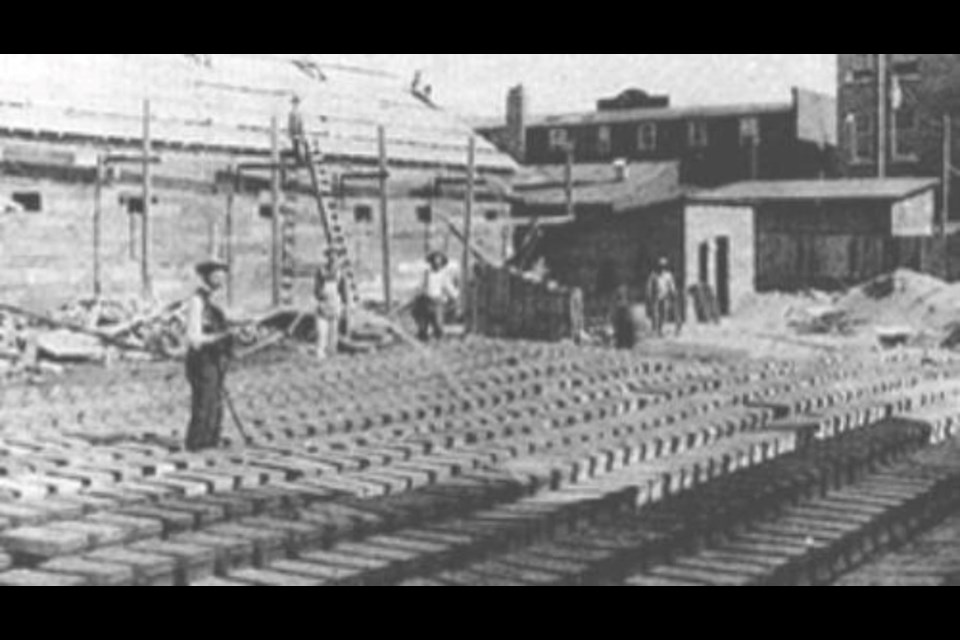

Its story began in 1907, when David L. Brown — fondly known as the “Cement King” — established the business on Long Lake Road in the city’s south end, becoming the first manufacturer of concrete products in the Sudbury area.

Back then, casting the blocks was a laborious process. The concrete was mixed by hand and poured into wooden molds. Once the molds were removed, the blocks were left in place to cure, and water was periodically sprayed over them to prevent them from drying out during the process.

The company changed hands in 1958, with business partners Johannes Herold and Taisto Eilomaa acquiring the operation.

By that point, the production rate had improved thanks to a small, automated machine that was used to cast the blocks. But because they still had to be moved by hand, the company could only produce about 800 blocks per day.

That changed a few years later, when Brown’s upgraded its equipment to a fully automated block machine, boosting production to 5,000 blocks per day.

Want to read more business stories from the North? Sign up for our newsletter.

Under Herold and Eilomaa’s ownership, the business flourished, relocating to its current location on Herold Drive and marking a number of firsts: Brown’s manufactured the first metric-sized block in Canada in 1978; a year later, it became one of the first manufacturers of concrete pavers in North America; and in 2007 it introduced to Ontario a unique permeable paving system called AquaPave.

Herold and Eilomaa’s successful partnership — which was anchored by mutual respect and friendship — lasted for 37 years until Eilomaa exited the business to pursue other interests.

Current ownership remains with the Herold family, with three generations now involved in its operation.

Family matriarch Erna, Johannes’ wife, is still heavily involved in the business, while sons Manfred and Ralph serve as president and vice-president, respectively, and Ralph’s son, Adam, is a plant foreman.

A familial closeness permeates the business, Scott said, with many employees marking multiple decades with the company.

Prior to the pandemic, staff gathered to celebrate one worker's 50-year employment history with the company, something Scott called a “once-in-a-lifetime event.”

“When you use the analogy of a ‘family business,’ I really don’t think it could be more true than what we are here,” Scott said. “When you’re a part of Brown’s, it really is a tight-knit group of people.”

The company employs between 50 and 60 people throughout the year, and Brown’s is always recruiting, Scott said.

With more long-term workers hitting retirement, it’s creating opportunities for younger employees to move up, bringing a renewed energy and enthusiasm to the job, he noted.

“As we get some of the key positions filled with people who are younger and have more years ahead of them, they have ideas about how we can improve things, and that’s a really positive thing,” said Scott, who's been with Brown's for 16 years.

“They see things a little bit different than maybe somebody who’s on the tail end of their career, so the influx of young blood into the business has been really positive.”

But the core of the business has been built on long-lasting partnerships that have endured for decades.

Some of Brown’s longest-standing clients and dealers first came aboard 50 or 60 years ago, and Scott said the company is mindful of those existing partnerships while also looking for ways to grow.

“Imagine a relationship with a company where our current owner’s father was dealing with one of our dealers’ mothers 50 years ago — that’s how far those relationships stand,” Scott said.

“We’re always very respectful of the relationships that were built before…. If you can respect the people that you do business with and there’s an integrity with what you do, I think it’s very easy to have those 40, 50-year relationships.”

Being in business for well over a century, the company has faced just about every challenge imaginable: economic downturns, labour shortages and, of course, at least one historic pandemic.

Scott believes Brown’s has weathered the storm because of its forward-thinking approach, considering what the market needs not just now, but what it will need 10 or 15 years from now.

“We’ve updated our (business) plan to really stay current to be able to manufacture the latest types of products, and I think that’s really where the success lies: to constantly be ready to change the way to do the business that’s being done at that time,” he said.

“I think, for a company like ours, it’s about seeing where the future is and ensuring that you’re a part of it.”